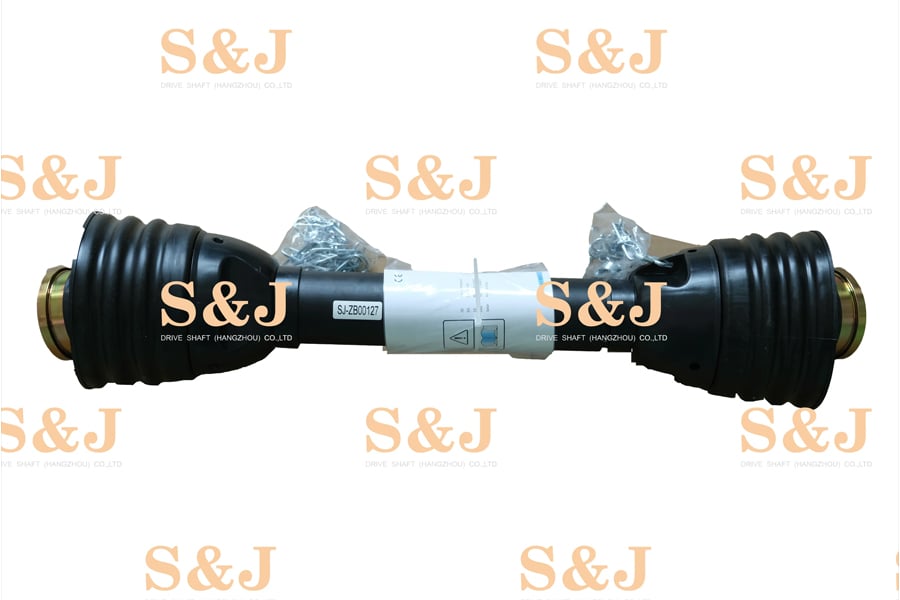

The Basics of PTO driveshaft assembly with clutch

PTO driveshaft assembly with clutch is an essential component in many agricultural and industrial machines. This assembly is responsible for transferring power from the engine to the attached equipment, allowing for efficient operation. Understanding the key elements of this system is crucial for proper maintenance and operation.

How Does a PTO Driveshaft Assembly Work?

A PTO driveshaft assembly with clutch works by connecting the power source, typically a tractor's engine, to the driven equipment. The clutch allows for disengagement of the driveshaft when needed, providing control over power transfer. This mechanism enables the equipment to operate independently of the engine when necessary.

Benefits of Using a PTO Driveshaft Assembly

There are many benefits to using a PTO driveshaft assembly with clutch. One significant advantage is the ability to easily connect and disconnect equipment, allowing for versatility in operations. Additionally, the clutch mechanism provides safety by preventing accidental start-ups when the equipment is not in use.

Common Issues with PTO Driveshaft Assemblies

Like any mechanical component, PTO driveshaft assemblies with clutch can experience issues over time. Common problems include worn clutch plates, damaged bearings, and misalignment of the driveshaft. Regular maintenance and inspections are essential to prevent these issues and ensure optimal performance.

Choosing the Right PTO Driveshaft Assembly

When selecting a PTO driveshaft assembly with clutch, it is crucial to consider the specific requirements of the equipment and application. Factors such as power rating, shaft length, and clutch type should all be taken into account to ensure compatibility and reliability. Consulting with a professional can help determine the best option for your needs.

Installation and Maintenance of PTO Driveshaft Assemblies

Proper installation and regular maintenance are key to maximizing the lifespan of a PTO driveshaft assembly with clutch. Care should be taken to align the driveshaft correctly, ensure proper lubrication, and inspect for any signs of wear or damage. Following manufacturer guidelines and recommended maintenance schedules is essential for long-term performance.

If you are looking to upgrade your PTO driveshaft assembly with clutch, there are several options available on the market. Upgraded assemblies may offer improved durability, higher power ratings, and enhanced clutch performance. Be sure to research different options and consult with a knowledgeable supplier to find the best solution for your needs.

Safety is paramount when working with PTO driveshaft assemblies with clutch. Always follow proper safety procedures when installing, operating, and maintaining this equipment. Avoid wearing loose clothing and jewelry around moving parts, and be cautious when working with heavy machinery. Regularly inspect safety guards and covers to prevent accidents.

PTO driveshaft assemblies with clutch are commonly used in a variety of applications, including agricultural machinery, construction equipment, and industrial machinery. These assemblies play a vital role in powering implements such as mowers, balers, and pumps, allowing for efficient and reliable operation in various settings.

Overall, a PTO driveshaft assembly with clutch is a critical component in many types of machinery, providing the necessary power transfer for effective operation. By understanding how these assemblies work, the benefits they offer, and how to properly maintain them, you can ensure optimal performance and longevity for your equipment.